Good [morning/afternoon], everyone.

It is my great pleasure to welcome you all to this exciting learning journey through our UNIT STANDARDS, 260. Whether you are here to gain new knowledge, sharpen your skills, or explore a new field, this UNIT STANDARDS 260 is designed to support and challenge you at every step.

Throughout this course, you will be introduced to important concepts, practical applications, and real-world scenarios that will enhance your understanding and competence in laying out, erecting, and installing steel structures as part of metal fabrication operations. People credited with this unit standard can prepare material and equipment; inspect and prepare an erection and installation site; and erect and install a steel structure. We have structured the content to be interactive, engaging, and aligned with your professional growth goals.

We encourage you to participate actively, ask questions, and collaborate with your peers. Remember, learning is not just about acquiring information, but also about applying what you learn in meaningful ways.

On behalf of the training team, I wish you the very best. Let’s make this UNIT STANDARDS a productive and enjoyable experience.

Welcome once again—and let’s get started

- Trainer: Filipus Lamek

Course Summary: Properties of Metals

Level: 2

Program: Metal Fabrication Training

Course Description:

This course introduces Level 2 metal fabrication trainees to the fundamental properties of metals and their significance in fabrication and manufacturing processes. Trainees will explore physical, mechanical, and chemical properties of common industrial metals and alloys, developing the knowledge required to select, cut, shape, join, and finish metal components effectively and safely.

Learning Outcomes:

By the end of this course, trainees will be able to:

-

Identify and describe key physical properties of metals, including density, melting point, and conductivity.

-

Understand mechanical properties such as strength, hardness, ductility, malleability, and toughness.

-

Recognize how thermal and electrical conductivity affect metal use in fabrication.

-

Explain how metals react to stress, force, and heat, and how these responses guide material selection.

-

Distinguish between ferrous and non-ferrous metals and understand their typical uses in fabrication.

-

Relate metallurgical properties to practical applications, including welding, forming, and machining processes.

Topics Covered:

-

Classification of metals (ferrous vs. non-ferrous)

-

Physical properties: density, melting point, thermal and electrical conductivity

-

Mechanical properties: strength, hardness, ductility, elasticity, toughness, malleability

-

Chemical properties: corrosion resistance, reactivity

-

Alloying and its effects on metal properties

-

Common industrial metals: steel, aluminum, copper, brass, stainless steel

-

Practical implications for fabrication and welding

Assessment:

Trainees will be evaluated through a combination of:

-

Practical demonstrations and hands-on activities

-

Short quizzes and worksheets

-

Group discussions and case studies

-

Final project or assessment task demonstrating knowledge application in fabrication settings

Duration:

40 Notional hours weeks .

Facilitator; Gideon Shikulo

Contact details :0812517880

Email:gshikulo@vvtc.edu.na

- Trainer: Gideon Shikulo

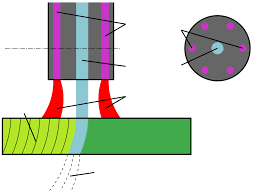

This unit standard is intended for those who carry out basic rigging and safe lifting practices as

part of metal fabrication operations. People credited with this unit standards are able to plan and

prepare for load slinging as well as to sling load.

This unit standard is intended for those who works as Welders and Boilermakers.

- Trainer: Shiwoovanhu Sheunye

This unit standard is intended for those who lay out and fabricate work pieces and components using the calculation method as part of metal fabrication operations. People credited with this unit standards are able to calculate true lengths of work pieces and components; calculate the positions of holes in steel sections and plates; fabricate work pieces and components

- Trainer: Filipus Lamek

- Trainer: Gideon Shikulo